We were contacted by a number of woodworkers who had been using domestic plug in remote control adaptors with their dust extractors. Inevitably over time the units burnt out, and we were challenged to find a more robust solution.

Our dust extractor remote control switch is in a different league to the other 'hobby' units which are available. Built from high quality industrial specification components, in an incredibly robust enclosure, it is designed for heavy professional use.

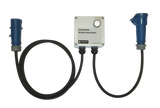

For extractors with a simple on/off switch, the remote control simply plugs in between it and the socket.

Where the extractor has an NVR switch, it must be bypassed using our NVR Bypass Kit - (only possible for NVRs with 4 terminals). Otherwise, each time the remote turns on the power, the start button on the tool would also have to be pressed. To retain the original tool's NVR either as it is a useful safety feature or if the NVR has 5 terminals and therefore cannot be bypassed, the Remote Control for Dust Extractors Retaining an NVR – Tough Leads provides the solution.

See our guide to dust extractor remote and automatic controls for further information.

Simply plug in the standalone remote control unit, and then plug your extractor into it. The unit is available with a range of connectors.

Pressing the on button on any of the remote controls turns the unit on, and pressing the off button on any remote turns it off (or off after the pre-set period with the time delay option). A total of 20 remote controls can be used with each unit.

Available with two operating options:

- Simple on/off - When the remote control 'ON' button is pressed the unit turns on, when the 'OFF' button is pressed it turns off immediately.

- Time delay - When the remote control 'ON' button is pressed the unit turns on, when the 'OFF' button is pressed it turns of after 10 seconds.

Supplied with 1 key fob (second to left). Visit the remote key fobs and switches page for additional switches with a range from 40-120m. Up to 20 remotes can be paired (this requires the front cover of the unit to be removed) with each control.

Our extractor controls are the only ones on the market which use an industrial contactor instead of a relay to switch the extractor. Other units use a relay, which is a cheap, compact way of controlling resistive loads. The issue is that any power tool with a motor creates an inductive load (further explanation of load types can be found here). When the relay contacts open to turn the tool off, the stored inductive energy in the motor coil is discharged, resulting in a damaging arc across the terminals, which can eventually cause the relay to fail. We use a high quality contactor instead of a relay. Contactors work using the same principle, but they are much larger and far better suited to switching higher current inductive loads. The picture below shows the sheer size difference between a typical contactor (left) and relay (right); when it comes to switching inductive loads, contact size really does make a difference.

Specification:

- Click here for the user manual.

- Extremely robust IP66 rated enclosure, dimensions L125mm x W125mm x D100mm.

- 16mm blue indicator shows when the extractor is on.

- With the time delay unit, the delay is supplied set to 10 seconds. Any specific delay can be requested when ordering, and it can also be user adjusted by removing the front cover of the enclosure.

- Range (plain line of sight) up to 40m with included fob, using an encoded 433Mhz signal to reduce interference. Up to 120m range achievable with the heavy duty remote.

- Contactor rating:

| Unit | Resistive | Inductive |

| 230v 13A | 20A (AC-7a) | 6.4A (AC-7b) |

| 230v 16A | 40A (AC-7a) | 15A (AC-7b) |

| 110v 16A | 32A (AC-1) | 18A (AC3) |

| 415v 16A | 63A (AC-7a) | 20A (AC-7b) |

- 2m in, 0.4m out industrial specification H07RN-F rubber cable specifically manufactured for harsh environments. Find out what’s so special about this cable.

- As a safety feature, the remote unit always defaults to off when the power into it is disconnected.

- May be wall mounted.

- PAT tested.

Advantages of a remote system:

- Reduces dust, improving the workshop environment.

- Supports compliance with HSE requirements.

- Saves power by running the extractor only when needed.

- Saves time.

- Ensuring dust extraction is always powered up when a tool is in use may improve tool performance.

- Reduces noise.

- Reduces heating bills (where extractor vents outside).

Connector Options:

Please use the guide below to ensure that the correct connectors are ordered, using the colour and diameter if unsure.

| Connector | Details |

|

UK 13A

|

|

230v 16A CEE7/7 European

|

|

230v 16A IEC 60309

|

|

110v 16A IEC 60309

|

|

|

415v 16A IEC 60309

|